1. D Deslandes and K Wu, "Integrated microstrip and rectangular waveguide in planar form,"

IEEE Microwave and Wireless Components Letters, vol. 11, no. 2, pp. 68–70, 2001.

2. N Ranjkesh and M Shahabadi, "Reduction of dielectric losses in substrate integrated waveguide,"

Electronics Letters, vol. 42, no. 21, pp. 1230–1232, 2006.

3. MD Fernandez, JA Ballesteros, and A Belenguer, "De sign of a hybrid directional coupler in empty substrate integrated waveguide (ESIW),"

IEEE Microwave and Wireless Components Letters, vol. 25, no. 12, pp. 796–798, 2015.

4. RMA Lee, J Jin, I Robertson, and A Farzamnia, "Integrated waveguide slot antenna and cavity filter using hollow SIW in LTCC technology," In:

Proceedings of 2015 1st International Conference on Telematics and Future Generation Networks (TAFGEN); Kuala Lumpur, Malaysia. 2015;pp 82–85.

5. CG Hynes and RG Vaughan, "Empty substrate integrated waveguide antenna array," In:

Proceedings of 2018 IEEE International Symposium on Antennas and Propagation & USNC/URSI National Radio Science Meeting; Boston, MA. 2018;pp 1027–1028.

6. KJ Russell, "Microwave power combining techniques,"

IEEE Transactions on Microwave Theory and Techniques, vol. 27, no. 5, pp. 472–478, 1979.

7. D Deslandes and W Wu, "Single-substrate integration technique of planar circuits and waveguide filters,"

IEEE Transactions on Microwave Theory and Techniques, vol. 51, no. 2, pp. 593–596, 2003.

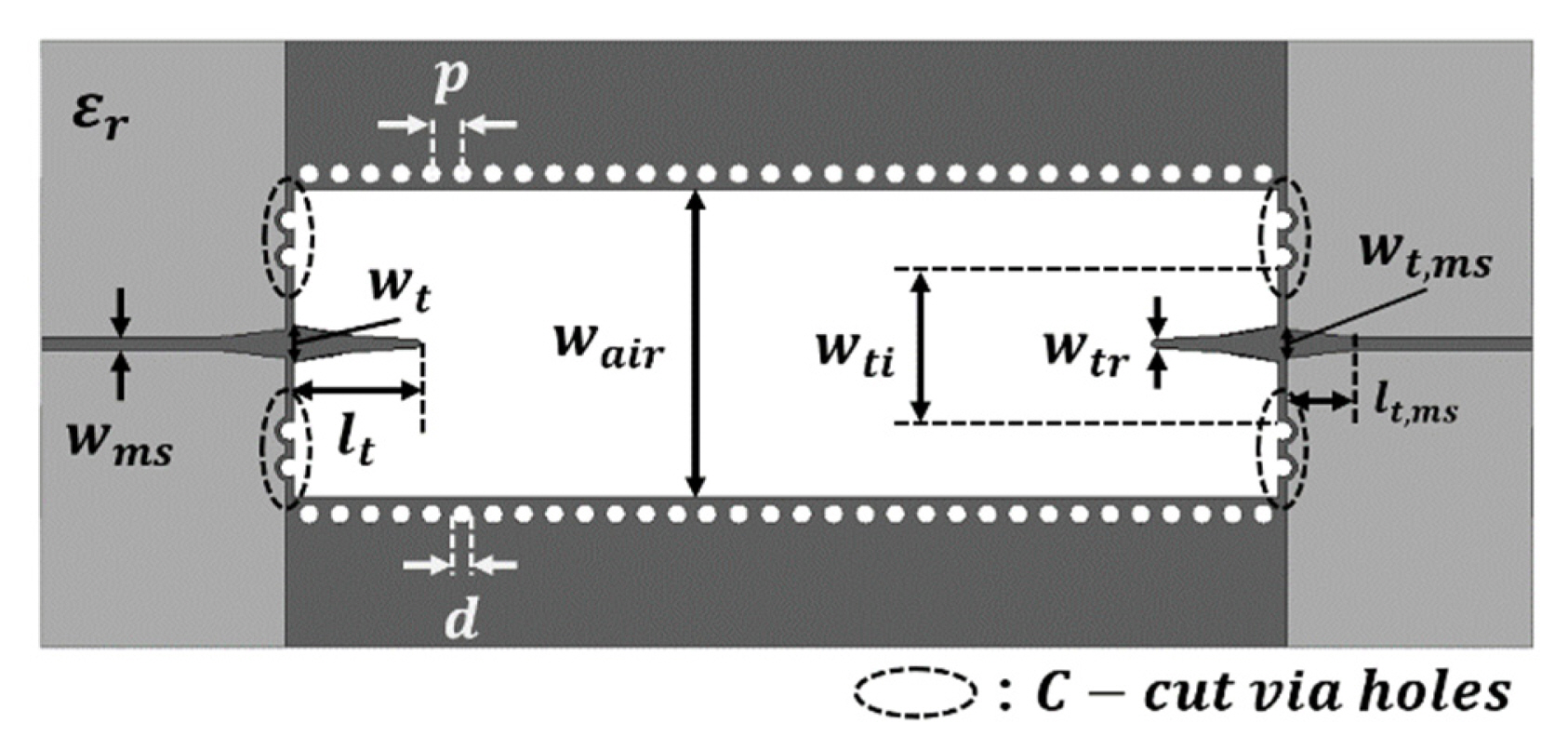

8. H Esteban, A Belenguer, JR Sanchez, C Bachiller, and VE Boria, "Improved low reflection transition from microstrip line to empty substrate-integrated waveguide,"

IEEE Microwave and Wireless Components Letters, vol. 27, no. 8, pp. 685–687, 2017.

9. X Jiang, "Two new Ka-band traveling wave power divider/combiner designs," M.S. thesis, North Carolina State University. Raleigh, NC, 2001.

10. Y Zhang, K Yang, X Ren, S Xie, and L Yimeng, "A study on novel broadband Ku-band spatial power divider/combiner," In:

Proceedings of 2013 IEEE International Conference on Microwaves, Communications, Antennas and Electronic Systems (COMCAS); Tel Aviv, Israel. 2013;pp 1–5.

11. K Song, W Lu, S Guo, and Y Fan, "Four-way hybrid SIW/microstrip-line power divider with improved output isolation,"

Electronics Letters, vol. 55, no. 1, pp. 36–38, 2019.